DESCRIPTION

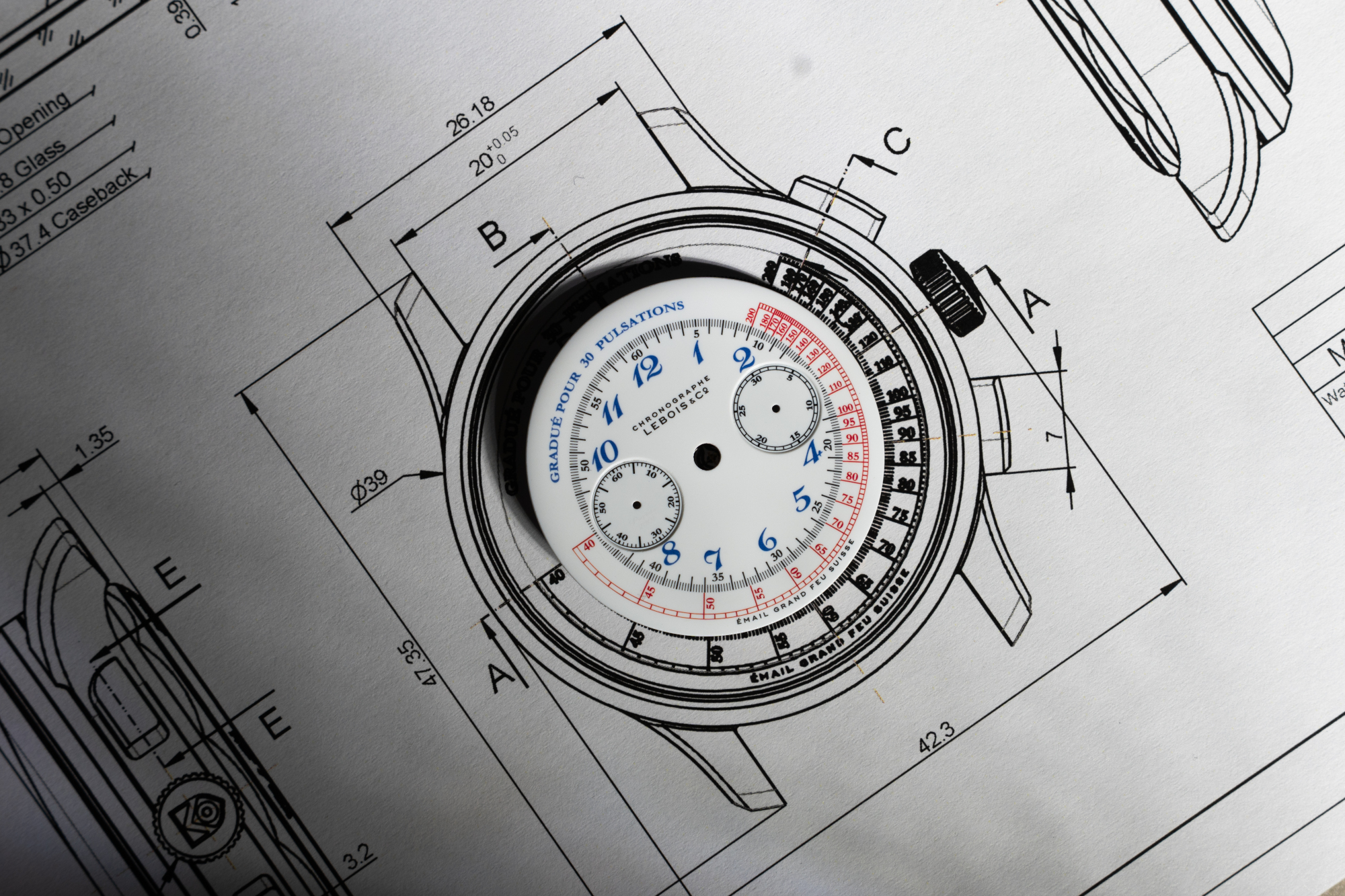

Crafted to celebrate the 25th anniversary of WatchProSite, this special edition Heritage Chronograph by Lebois & Co is a tribute to horological passion, community, and craftsmanship.

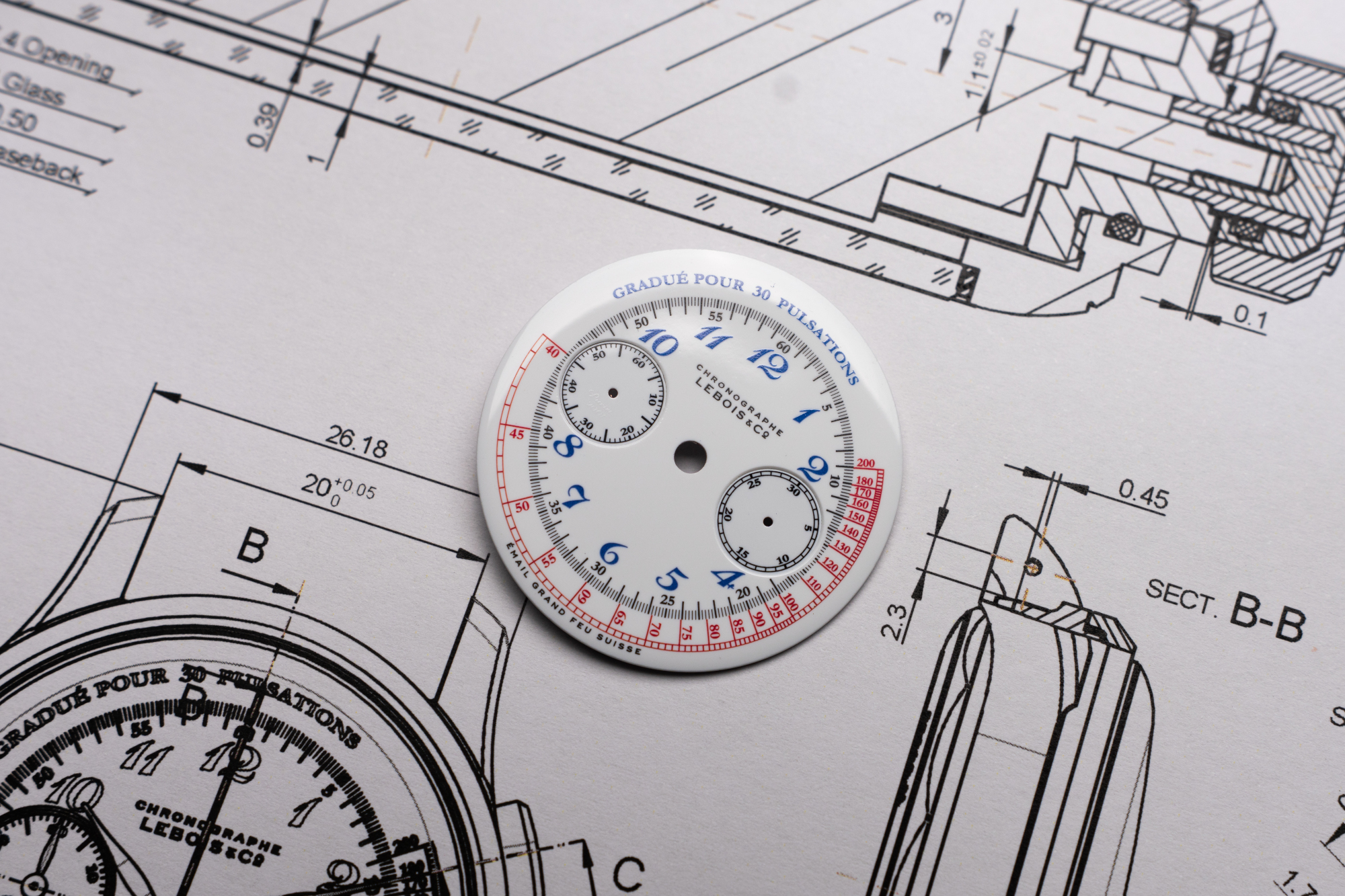

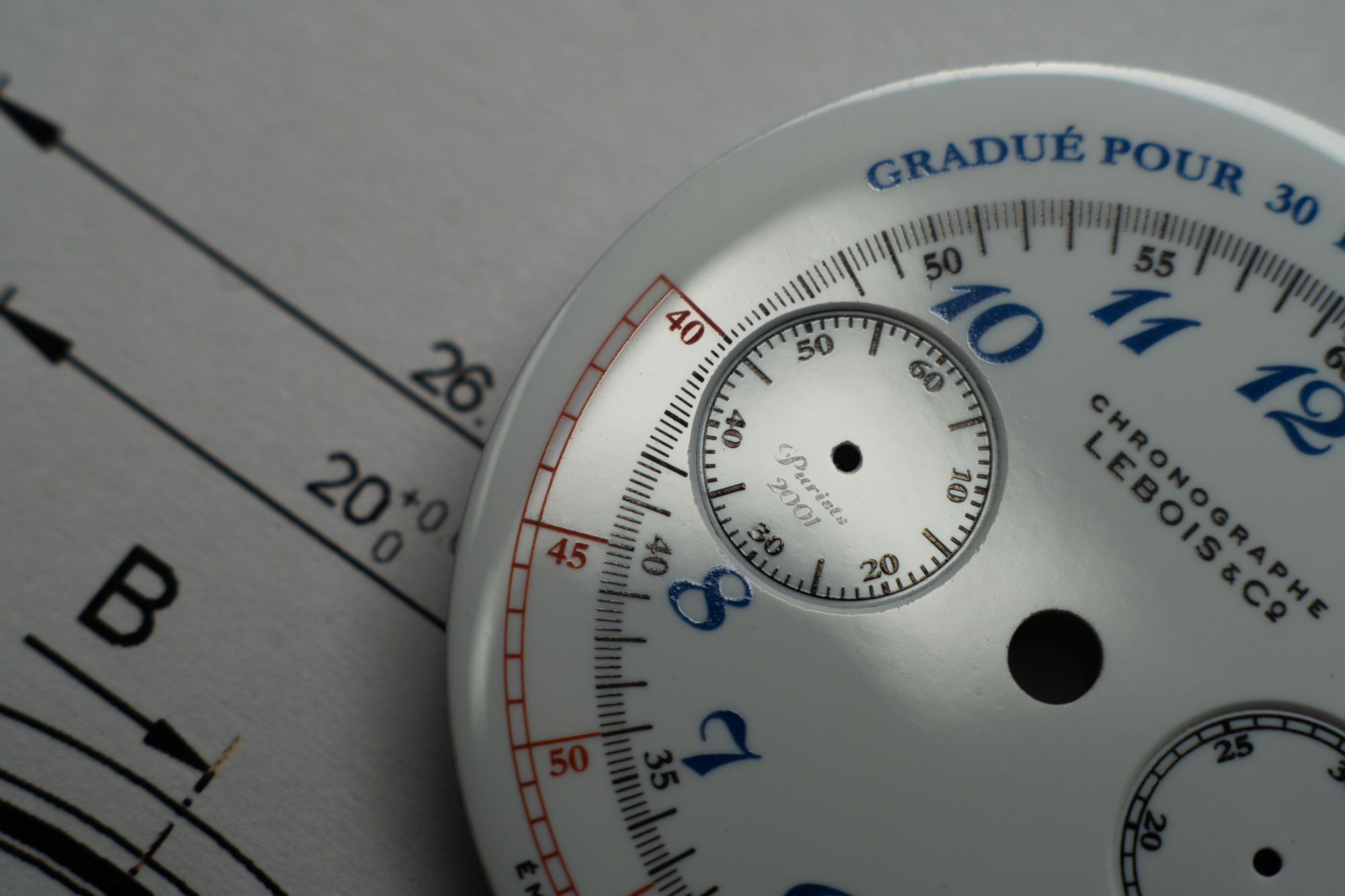

At the heart of this limited edition is a Swiss-made Grand Feu enamel dial, handcrafted by Donzé Cadrans in Le Locle. It features a multi-part construction with individually produced subdials, layered colors, and a hidden “Purists 2001” signature which is only visible at certain angles. The enamel dial is paired with a Swiss column wheel chronograph movement from La Joux-Perret, visible through the exhibition caseback.

The P25 edition is available exclusively to the WatchProSite community and will not be publicly listed. Each piece will be made to order, based on final preorder quantities, ensuring exclusivity and personal relevance to those who helped shape this collaboration.

SPECIFICATIONS

Block "pp-specifications-coquille" not found

MOVEMENT

CALIBER

TYPE

WINDING

CHRONOGRAPH

POWER RESERVE

VIBRATIONS

JEWELS

LC-450

MECHANICAL

HAND-WOUND

COLUMN-WHEEL

60 HOURS

28,800 VPH

23

A Journey into Enamel

Behind every enamel dial lies a process shaped by patience, fire, and unforgiving precision. From raw copper to luminous Grand Feu, this photo series documents each stage of the creation — revealing what it truly takes to transform elemental materials into a timeless watch dial. Each step is handcrafted in Switzerland by master artisans. No shortcuts. No second chances. Only the flawless remain.

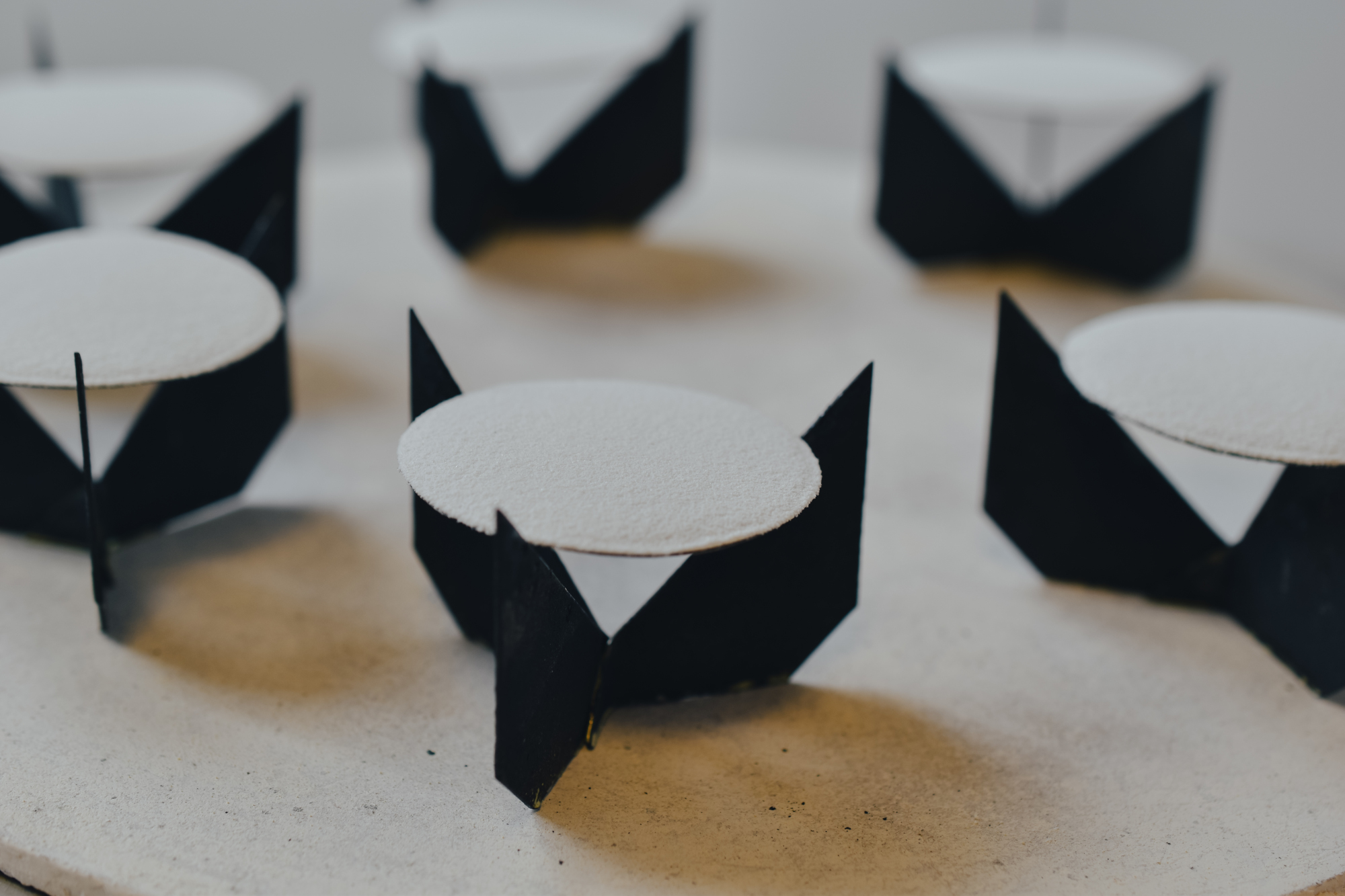

The base takes shape

A thin copper disc is cut and formed to match the dial’s exact curvature. This blank will carry not only layers of enamel, but the weight of precision.

Anchored by hand

Two small copper feet are manually pinned and soldered in place. They allow the finished dial to mount perfectly to the movement — misalignment is not an option.

Purified by hand

The raw enamel powder — made from crushed mineral glass — is ground and washed in water to remove impurities. This slow, tactile process ensures a clean, even surface after firing.

The first coat

A thin layer of enamel is applied to both sides of the dial. This isn’t aesthetic — it balances internal tension during firing. Enamelling on both sides is essential for stability.

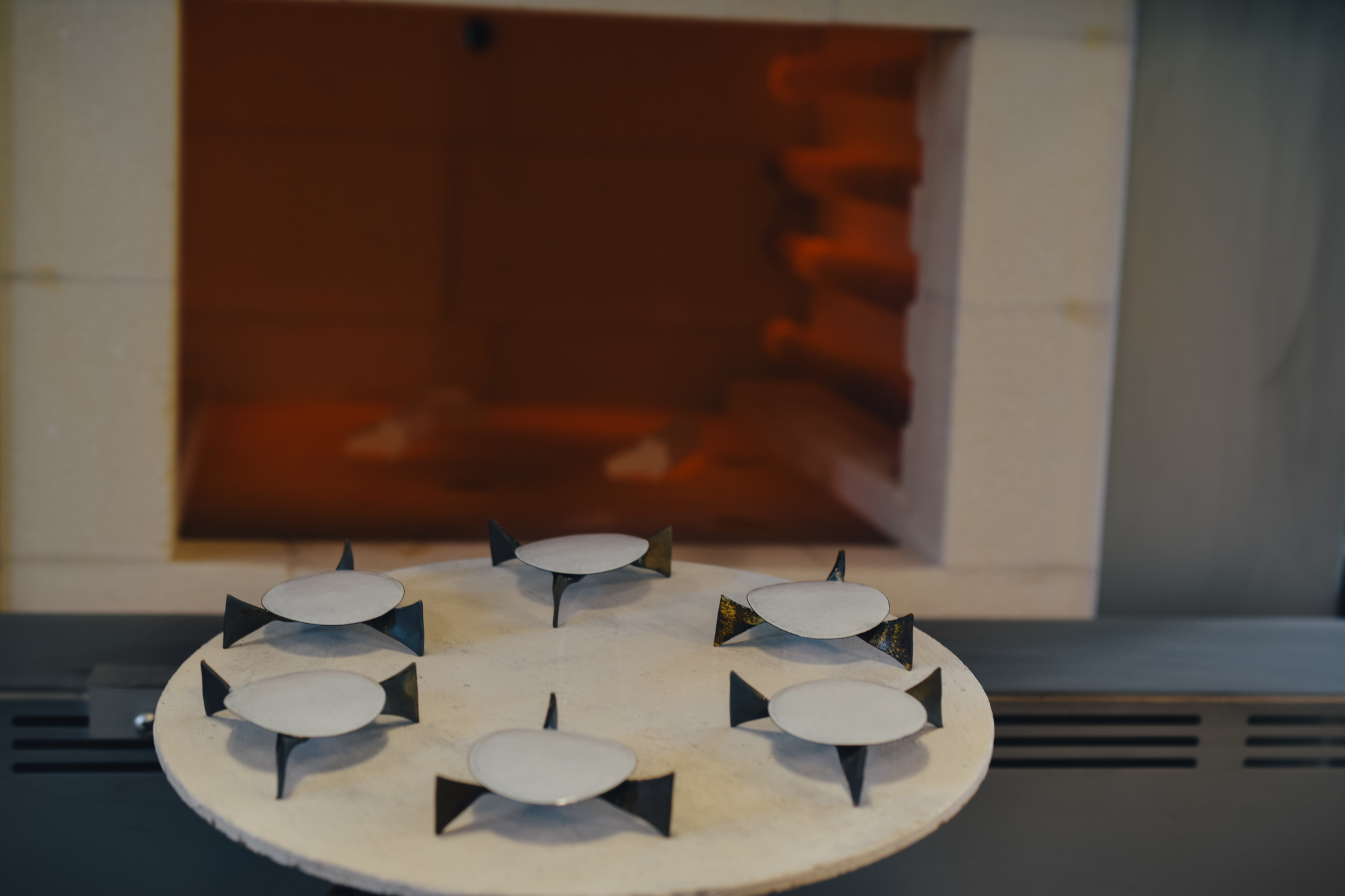

Fired at 800°C

The dial enters the kiln. At this stage, it's just enamel powder on copper — but under intense heat, glass begins to fuse, and the surface gains depth. Most dials don't survive the first few firings.

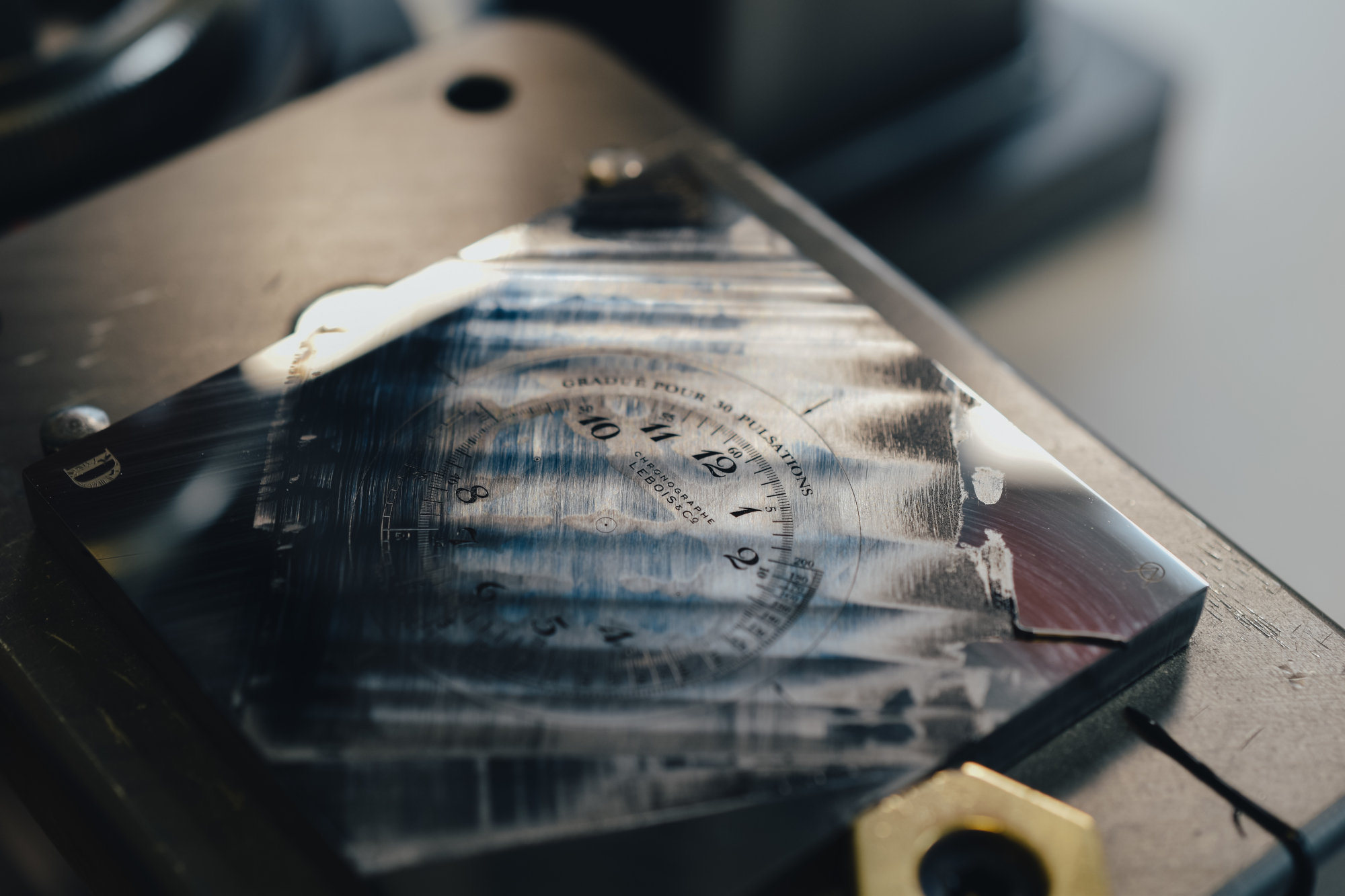

Printed, layer by layer

Each color is pad-printed one by one, aligned with extreme precision. On a curved enamel surface, any shift — even a fraction — means the dial must be scrapped.

Three parts, one dial

This dial isn’t a single piece. The subdials are produced separately, then set into place and filed flush. The result: perfect integration, made invisible by skill.

Only the flawless remain

After the final firing, each dial is checked under magnification and projection. Print tension, shape, and enamel consistency must be perfect — or it's rejected.

The final surface

The result: a luminous, tension-free dial, deep in tone and rich in character. From copper to color, every step leaves its mark — even the invisible ones.

FAQ

Please find the frequently asked questions below. If your question isn’t listed, feel free to contact Bill, one of the moderators, or Lebois & Co directly.

How will the purchase be handled?

- All purchasing and payment will be handled directly through Lebois & Co’s website.

- WPS will not act as a broker or intermediary, and you will not send money to any forum member.

- You will be redirected to an official ordering page once preorders go live, ensuring secure and traceable transactions.

What are the payment options and terms?

Lebois & Co offers two payment options for ordering:

-

Pay in Full

Pay the full amount at the time of order. -

50% Deposit

Secure your order with a 50% deposit. The remaining balance is due prior to shipment.

All prices are excluding VAT or applicable duties/taxes, which will be added at checkout based on the shipping country. Payment methods accepted: major credit cards, wire transfer, and crypto.

What happens if the project is cancelled or not completed?

- If the watch cannot be produced or delivered, refunds will be issued according to Lebois & Co’s terms.

Can I choose a specific limited-edition number (e.g., to match my Montblanc Minerva)?

-

Each caseback will be engraved with WATCHPROSITE and 25TH ANNIVERSARY, along with the engraving “1 OF XX”. The final “XX” will reflect the total production quantity confirmed after the preorder window. The total number of watches has not yet been finalized and will be set once we go into production.

-

In addition, every watch will carry a regular Lebois & Co serial number to ensure unique identification for service, registration, and authenticity purposes. These serial numbers are allocated by Lebois & Co and cannot be customized.

Will the case resemble the Minerva design?

- Yes. The design is directly inspired by vintage Minerva aesthetics, including case shape, finishing, and proportions. It’s a key part of what defines the P25.

Will there be an open caseback?

- Yes. The P25 will include an exhibition caseback, allowing a clear view of the movement inside.

When is the watch expected to ship?

- Delivery is expected early 2026, depending on final production timelines and demand. Updates will be communicated throughout the process.

When do we need to pay?

- Payments will follow one of the two options noted above.

- For those choosing the deposit route, you’ll pay 50% upfront when preorders open, with final payment due prior to shipment.